3D Printers have become a staple tool in today’s schools, libraries, corporate, and military environments. While we bring our ideas, and inventions, to life, with these versatile, and powerful tools, we inadvertently generate harmful emissions.

3D printer emissions

3D printer emissions

Ultra Fine Particles (UFPs) – The main exposure to UFPs is through inhalation. Owing to their size, UFPs are considered to be respirable particles. Contrary to the behaviour of inhaled PM10 and PM2.5, ultrafine particles are deposited in the lungs,[11] where they have the ability to penetrate tissue and undergo interstitialization, or to be absorbed directly into the bloodstream — and therefore are not easily removed from the body and may have immediate effect.[2] Exposure to UFPs, even if components are not very toxic, may cause oxidative stress,[12] inflammatory mediator release, and could induce heart disease, lung disease, and other systemic effects.[13] [14] [15] [16] A robust association has been observed between fine particulate levels and lung cancer, and cardiopulmonary disease.[17] The exact mechanism through which UFP exposure leads to health effects remains to be elucidated, but effects on Blood pressure may play a role. It has recently been reported that UFP is associated with an increase in blood pressure in schoolchildren with the smallest particles inducing the largest effect.[18]

For more detailed information on UFPs and references, please refer to this link.

Volatile Organic Compounds (VOCs) – Health effects include eye, nose, and throat irritation; headaches, loss of coordination, nausea; and damage to the liver, kidney, and central nervous system[46]. Some organics can cause cancer in animals; some are suspected or known to cause cancer in humans. Key signs or symptoms associated with exposure to VOCs include conjunctival irritation, nose and throat discomfort, headache, allergic skin reaction, dyspnea, declines in serum cholinesterase levels, nausea, vomiting, nose bleeding, fatigue, dizziness.

For more detailed information on VOCs and reference, please refer to this link.

Independent research

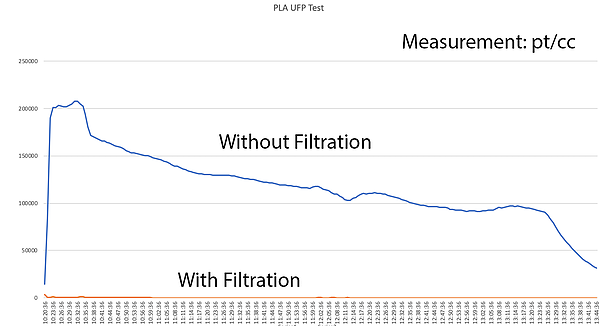

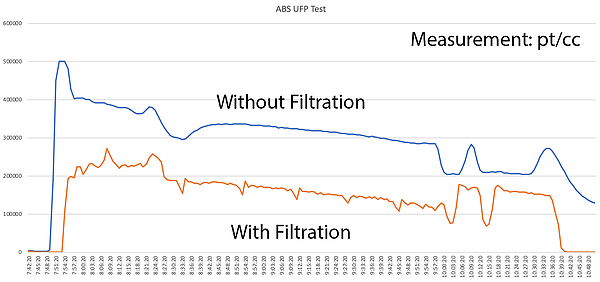

All filaments create harmful emissions and when using filaments that ran at average temperatures (185c – 230c) where PLA and ABS are used, the highest amount of emissions are produced. And the extruder and print bed together account for the highest number of emissions. In short, a 3d printer and the accompanying filaments even when used correctly, produce emissions.

For the full detailed study please refer to the following links:

-

Georgia Institute of Technology

-

Illinois Institute of Technology

-

UL

Have you read the safety sheet that comes with your filament?

All filaments are required to ship with a Material Safety Data Sheet (MSDS). If you read through the manual, you will come across “Use in a Well-Ventilated space”.

What’s in your PLA?

PLA is a popular and easily accessible 3d printing filament made of natural elements. Though you’re still inhaling emissions from melting plastic. With new and exciting composite filaments arriving on the marketplace, filaments like “Strong PLA” are blending PLA with acrylic material which when heated to melting point, formaldehyde gas is released. Similar to reading food labels, read the MSDS that comes with these new composite filaments.

A HEPA filter is all I need, right?

Unfortunatley no. HEPA filters address particles that are over 100 nanometers(nm) in size. UFP particles come in below 100nm. The UFPs that are produced from PLA, ABS, HIPS and other popular filaments are 15nm to 65nm. If the UFPs are not contained as they are generated, you can’t effectively remove them from the air.

What about a carbon filter?

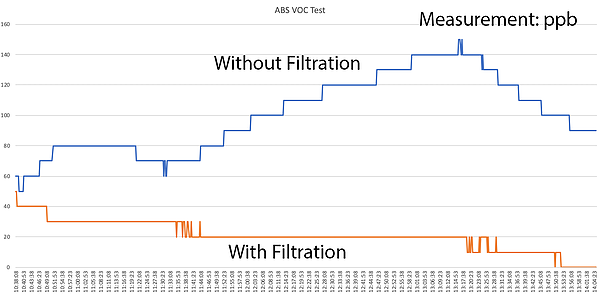

Carbon filters come in many configurations and we did exhaustive research in finding the proper size, shape, placement, treatments and composition in order to effectively reduce VOCs.

My 3d printer has doors! This works, right?

More 3d printers are coming equipped with basic doors or have optional third party acrylic boxes that go around the printer. While these offer basic protection against burns and drafts, they do very little in the way of removing the VOCs and UPFs. When you open the door or shift the box, you’re getting exposed to concentrated doses of UFPs and VOCs. Our proprietary system effectively reduces the UFP and VOC count so you are able to open the doors and adjust your printer without getting exposed to the concentrated levels of contaminates.

Can I install a ventilation system?

Yes, you can! Besides construction costs, permits, design, etc, installing ventilation can result in loss of sufficient heat within the 3d printer environment which can cause prints to crack and warp.